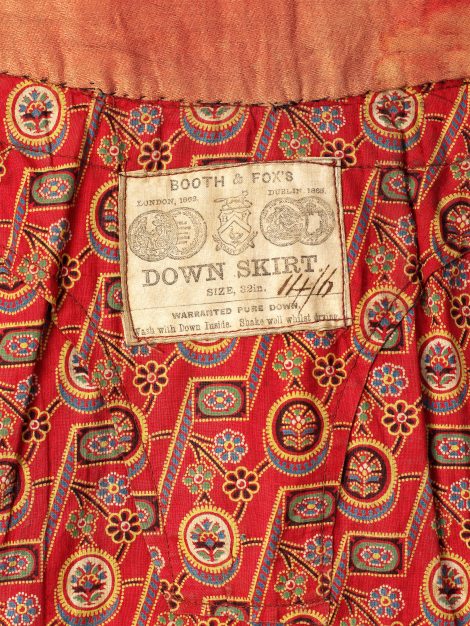

Label of red petticoat ‘Booth & Fox’s/ Down Skirt.’

These two cotton waist petticoats are quilted with down, combing the benefit of bulk, needed to provide the silhouette of contemporary fashion, and warmth without weight. Booth and Fox, feather merchants and manufacturers of the award-winning underskirts of which the red one is a typical example, advertised them as weighing ‘from 18 to 21 ounces, and yet, in addition to be as soft as cushions, can be washed with the down inside as readily as a quilt’, a major selling point, especially as the dyes were claimed to be fast. Other down-filled garments available included dressing gowns, vests, bustle pads and bust improvers.

The steps performed to produce our red petticoat can be found in an article describing a factory visit in the Cork Examiner of 22 July 1867. According to the author, the recently enlarged and modernised factory at Lavitt’s Quay, at the centre of the Irish city Cork, employed a staff of 450 and was powered by a 25 horse power steam engine ‘six days and four nights out of the week’. Premises and staff were separated into a feather cleaning department and a manufacturing department that produced the finished goods. Classed as trained workers, the quilters/manufacturers received higher pay than the cleaning department.

The journalist’s tour starts in the weighing or receiving room where ‘hundreds of bales’ are ‘examined, assorted, weighed’. Next stop are the washing rooms, ‘with hot and cold water tanks, through which a strong current is constantly propelled’. A mixture of chemicals purifies the feathers that are then rinsed and enter the steaming and drying apartments with ‘huge wire cases’ above steam pipes. ‘They are blown about, heated and freed from animal matter’. In the milling department, girls put the dried feathers into revolving wire cylinders with fans to remove the remaining dust. The feathers are passed through ‘picking rooms’ where women and girls ‘sit imbedded to the armpits’ in feathers, picking out the rougher ones. The quilting rooms are strictly separated from the cleaning department to prevent contamination and the journalist seems taken with the ‘well lit rooms, filled with quilting frames’ at which ‘girls and women stand working’. ‘The material of the covers is usually a chintz printed in various Indian-shawl patterns […] the designs of which, exhibited by Messrs. Booth and Fox, and manufactured expressly for them, are beautiful to the highest degree’. The amount and quality of quilting is ‘proportioned to the price to be demanded’ and the author praises one of the elaborate designs as ‘a positive work of art’. The final stop is the packing department from where the finished goods are sent out, many of them to be exported.

The description of the ‘Indian Shawl’ design chintzes perfectly matches that used on our red petticoat. Bright colours and printed fabrics were features of underwear at the time. Our Booth & Fox example is dyed in Turkey red, a strong bright red derived from the madder root, which originated from India, spreading westwards to Scotland where it was used from the late 18th Century. It could be washed frequently and therefore was a practical, and cheerful, choice for underwear, accessories, and quilts. The small, bright, discharge-printed pattern of this petticoat is typical of Turkey red fabrics.